The Sustainable Advanced Manufacturing (SAM) Project has been helping North East manufacturers to become more productive and sustainable by supporting projects that enhance their products, processes and technology for the past five years.

The programme – which was launched in May 2018 – has proven a huge success and benefit to the region, attracting national attention while forging an impressive reputation, as well as helping bring to market some notable new products and innovations.

To date, it has provided almost £2 million in grant funding to the region’s manufacturers, as well as providing practical and research support to over 300 SMEs, from sole traders all the way through to businesses employing hundreds of staff.

And with the programme set to run until June 2023, discussions are now underway as to how this significant support can remain accessible to the region following the end of European Regional Development (ERDF) funds.

The pioneering £10.9 million initiative is part-funded by ERDF, which invested £5.8 million, and the University of Sunderland and industry.

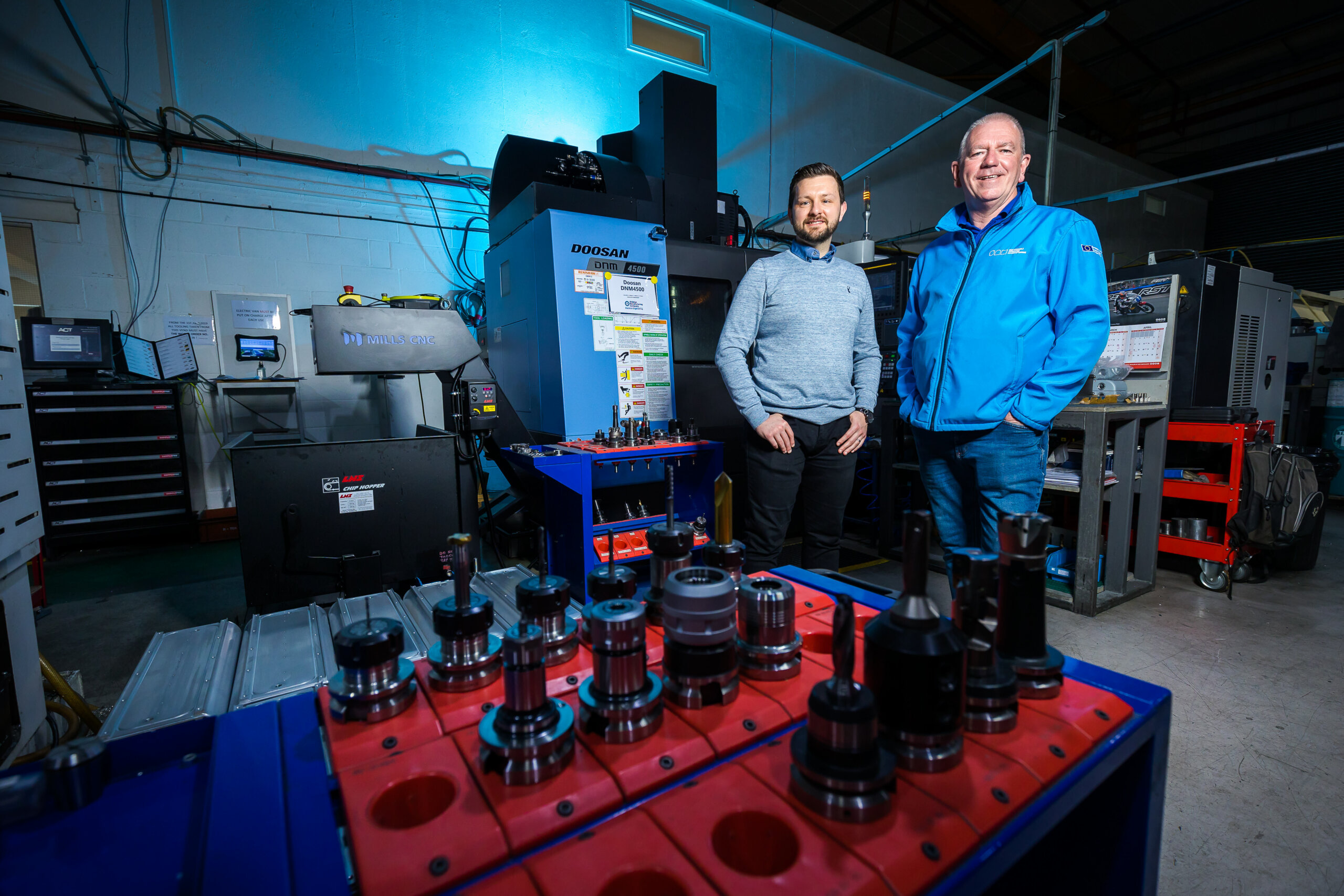

The project offers a range of assistance to eligible SMEs in the North East LEP area, allowing them to access and tap into the significant academic resources with the University’s Faculty of Technology, a specialist team of industrial experts and five distinct factories with more than £1 million worth of cutting edge equipment.

Through this, SAM is able to offer both practical and research support, ensuring businesses can access relevant knowledge comprising some of the region’s and industry’s best informed and experience practitioners, as well as access to the latest advanced manufacturing technology.

The SAM Project Technical Research and Development team has been drawn from industry with a diverse mix of backgrounds and skills to provide a unique and compelling offer of support to SMES in the region.

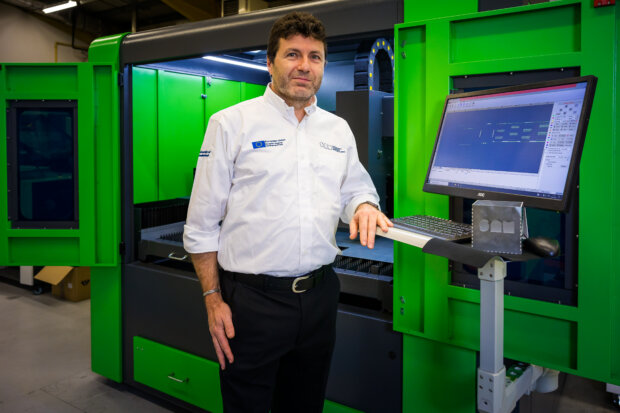

Roger O’Brien, project and technical lead at the SAM Project, said: “The SAM Project is, and has been a huge success, and we are delighted to be continuing to provide support to the region’s manufacturing sector, which is key to the regional economy, jobs, growth and position.

“Over the years, we’ve provided funding and support to hundreds of businesses and have witnessed firsthand the impact this has had, from safeguarding and creating jobs to transforming entire production lines. Last year alone we registered an additional 77 manufacturers onto the programme, as well as working with existing businesses, meaning 169 companies have now received support in the last 12 months alone.

“Since the pandemic and with the impact of Brexit, the nation’s manufacturing sector has faced more than its fair share of challenged. However, it has also provided opportunities such as re-shoring and bringing back in-house previously sub-contracted works, as well as business diversification.

“Now, more than ever, manufacturers need our support and the funding and support offered by SAM is key to ensuring many of the region’s SMEs are able to adapt and grow as we look to re-emerge from this crisis and keep Britain’s economy moving, and help prevent the UK from falling into a potential recession.”

The SAM Project has provided matched-funded grants of up to £50,000 to scores of SMEs, be it for capital, product validation, equipment and other financial inhibitors to drive the strategic development of both product and process.

The total grant pot was £2 million, which has supported approaching £6 million worth of private sector investment in new facilities and state of the art equipment, in nearly 80 businesses within the North East spread across all areas of the region and from a diverse mix of manufacturing sectors, from traditional engineering to those delivering cutting edge new products and processes.

An independent report commissioned to explore the impact of the SAM Project at the midpoint of the project also revealed that the programme helped create 270 jobs, over half of these directly as a result of SAM interventions and added over £47 million in gross value to the regional economy.

Two years on from that report and the success has magnified as the impact has continued to grow, with the project about to embark on a full impact assessment and evaluation for its full duration.

“Our fully-funded technical advice and support is what really makes the SAM Project stand out from your traditional business support schemes,” Roger added. “While there are many other grant funds out there to help businesses grow, there are very few – if any – and certainly none in the region, which offer the intensive, personalised, in-depth technical support that we do.

“We have delivered everything from concept designs, proof of concept studies, implementation support, factory layout, technology adoption and best practice, across the spectrum of advanced manufacturing. I am immensely proud of the support and benefit the project and team have made to the region, and hope this can continue to make a difference beyond June 2023.”

Roger concluded: “If you’re an SME manufacturer, then the engineers, researchers, grants and access to equipment are here to help you adapt to the inevitable process changes facing and to help take your business to the next level.

“Programmes like this are pivotal to ensuring the North East continues to lead the way in product, process and technology innovation – and we can’t stress enough how important it is that manufacturers get on board before this phase of support ends.

“There is only a set amount of time and technical support available, as well as very limited grant funds remaining, therefore – following the huge success – registration as soon as possible is highly recommended.”