North East engineering and manufacturing companies will be given support in driving operational excellence through Lean Tools & Techniques and Industry 4.0, with a series of events next month.

The Lean Workshop Group in collaboration with the Sustainable Advanced Manufacturing (SAM) Project are running two events at the Industry Centre in Sunderland on Tuesday 18 and Wednesday 19 April 2023.

The Lean Workshop Group is a consortium of eight of the most innovative suppliers to the manufacturing sector: Bosch Rexroth, Spitfire, SICK UK, Orgatex, Bosch Power Tools, Visual Management Technology, WERMA Signaltechnik and K Hartwall.Harnessing a wealth of expertise in their specialist fields, the partners will provide companies with insightful tips and practical takeaways that they can implement in their business to bolster operational resilience, enhance inter-department connectivity, improve efficiencies and strengthen its competitive position.

There will be an opportunity to participate in practical and interactive session, using advanced equipment from the partner companies to put into practice Lean Management and Industry 4.0 techniques. Key topics will be covered including Visual Management, 5S (Workplace Organisation), Standard Operation Development, Work Content and Workplace Design, Logistics Operations, KANBAN Systems, ANDON, Intelligent Sensor Technology, Fundamental Skills Training, Cordless Power Tools, Autonomous Mobile Robots and Industry 4.0 Applications.

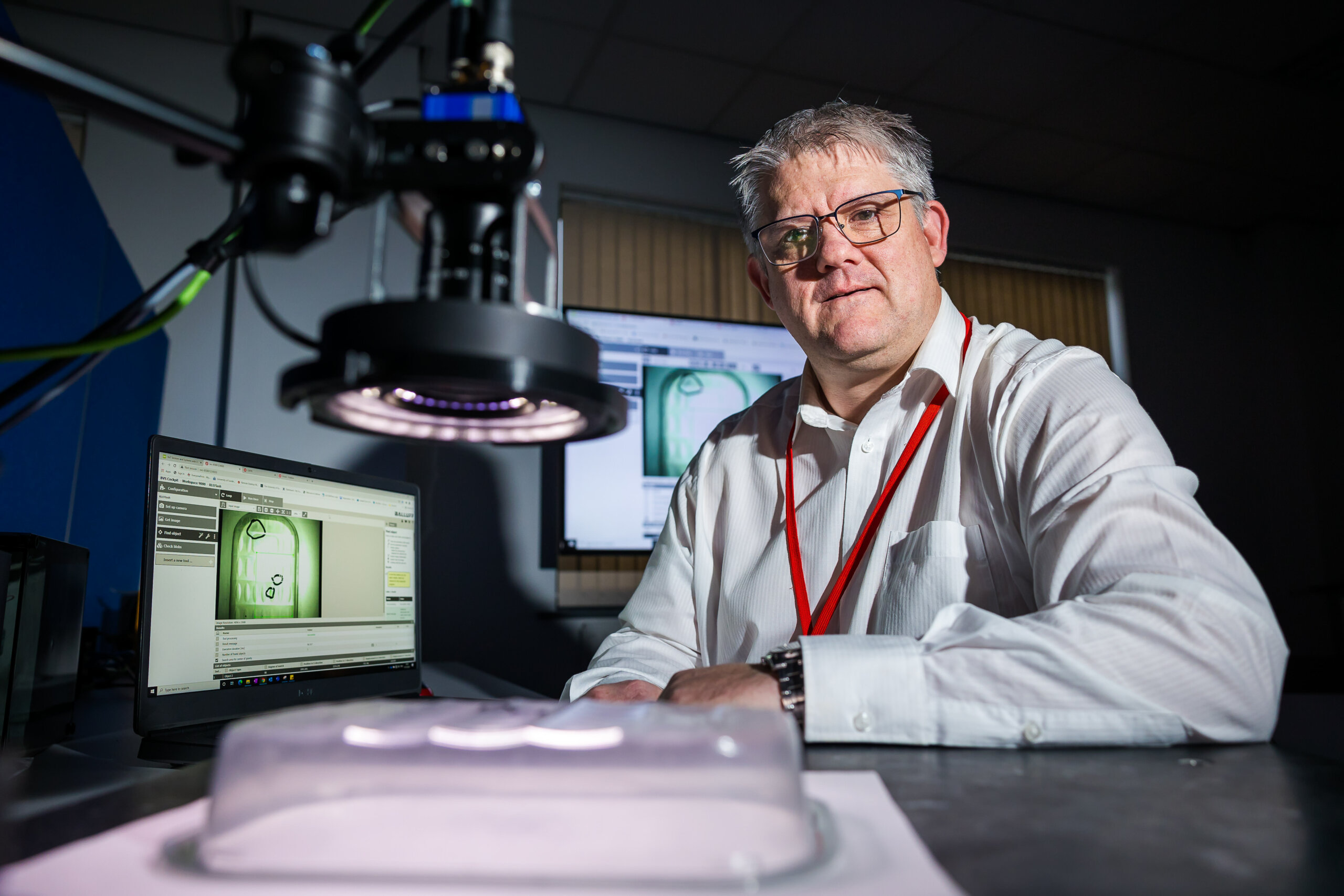

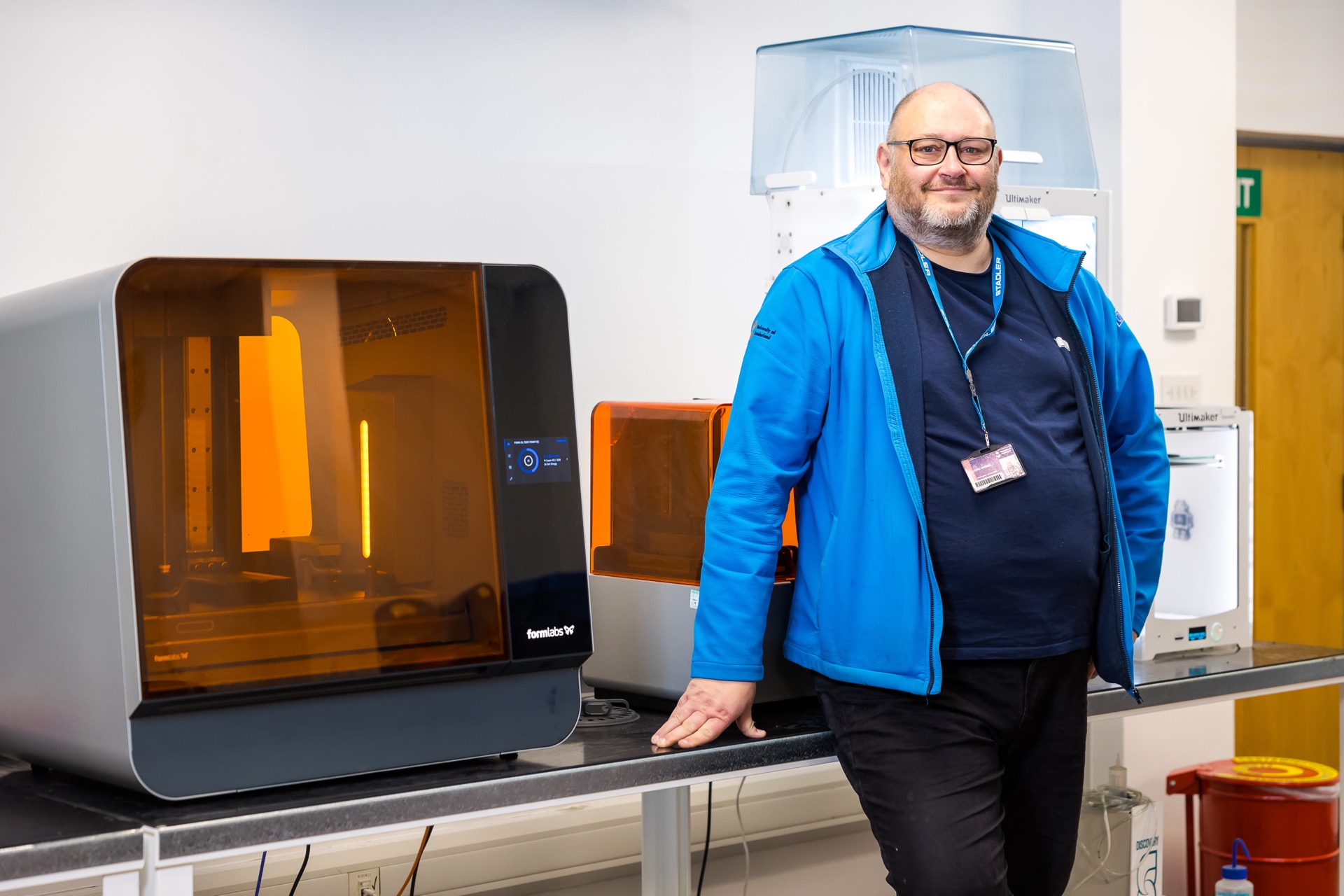

The events will be hosted by SAM, a £10.9m project to support the implementation of product and process development and the introduction of technology within the SME manufacturing base in the North East Local Enterprise (NE LEP) area.

Kevin Jones, partner at the Lean Workshop Group, said: “These workshops will be an excellent opportunity to review your processes, and listen to experts as they help move your company into the digital manufacturing age.

“Integrating lean management and Industry 4.0 into business processes to address pain points provides manufacturers with a host of benefits such as real time data to accelerate management, data driven quality control and training in virtual reality to improve working conditions.”

Roger O’Brien, Project and Technical Lead at SAM, added “We are pleased to be working with the Lean Workshop Group and promote areas of best practices to manufacturers in the region. The manufacturing sector is key to the North East and embracing the latest technologies that will be demonstrated in this event, and via our SAM facilities, will support companies to be more productive, competitive and meet some of the economic production challenges facing them in these challenging times. We encourage manufacturers to join us for this event for an insightful and thought provoking day.

The events will be held between 10am and 3pm on Tuesday 18 or Wednesday 19 April 2023 at the Industry Centre, Sunderland. For more information and to book click here