The sound of the Westminster Abbey organ during the Coronation of Kings Charles III this weekend will bring music to the ears of staff at an historic North East manufacturer.

Family-owned Durham organ maker and restoration specialist, Harrison and Harrison, built and installed the formidable Westminster Abbey organ in 1937 for the coronation of King George VI.

Since then, the organ has been a permanent fixture for some of the most important dates in the royal calendar, from royal funerals to weddings, Christmas and Easter services and christenings.

Positioned on the north and south sides of the abbey’s nave screen, the organ is an 84-stop, four manual instrument with two plain oak organ cases designed by the architect J. L. Pearson and decorated in gold and coloured by W. Butchart.

Jeremy Maritz, administrator at Harrison and Harrison Ltd, said: “Our staff take great pride in their work, and especially continuing to maintain the work undertaken by previous generations of the firm to provide musical instruments that accompany and enrich important national events like the coronation.”

Established in 1861, Harrison and Harrison today employs over 40 people at its Meadowfield workshop – as well as nine tuners based around the UK from London to Aberdeen – and has forged a global reputation for its dedication to its craft, building and servicing organs for customers across the globe, from Australia to the USA, South Africa, Japan, Sweden, Norway, Nigeria and Kenya.

Underpinning this success has been the company’s commitment to continually invest in its staff by training the workers of tomorrow in the niche skills required to preserve this historic craftsmanship, as well as the company’s dedication to constantly innovate and push industry boundaries.

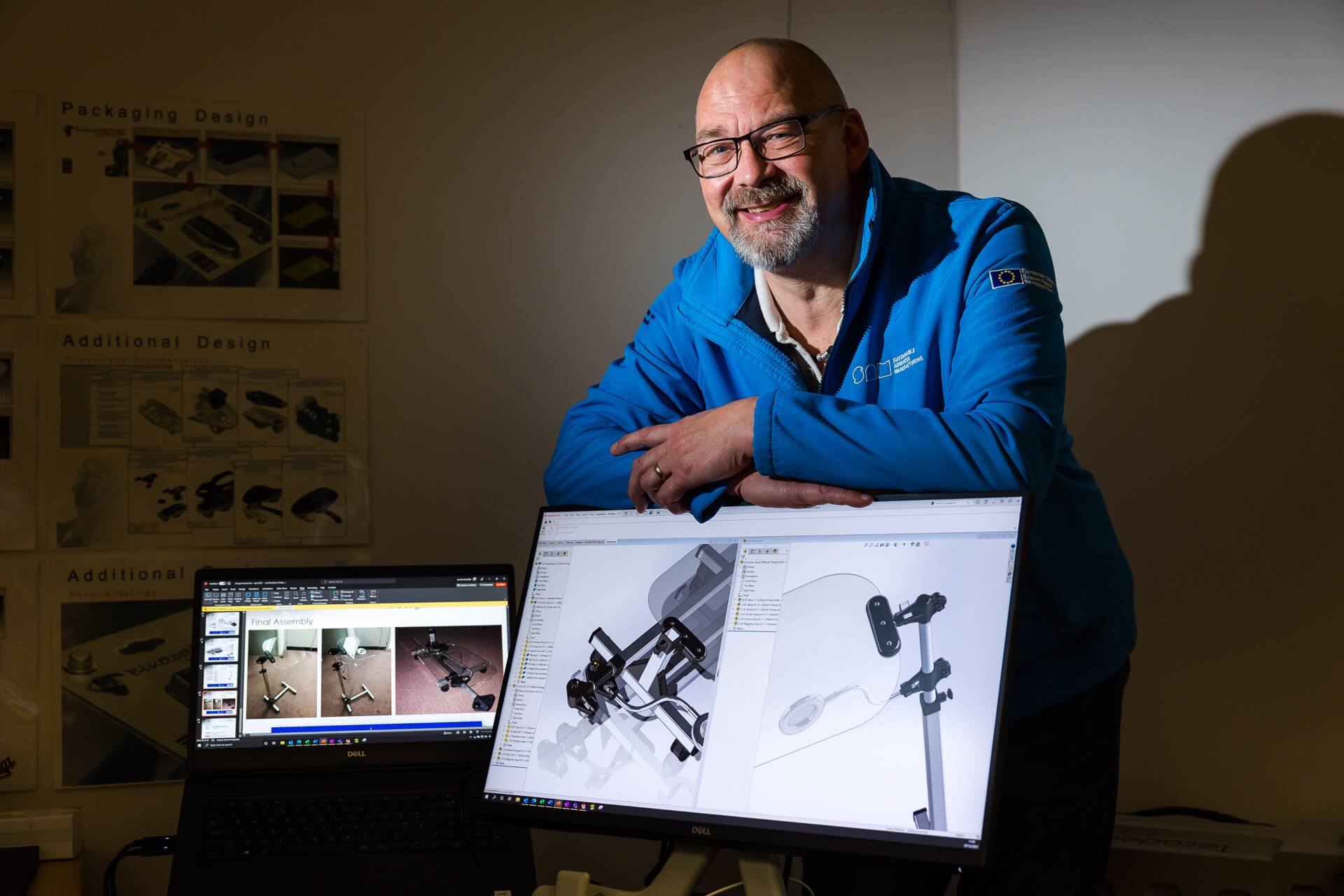

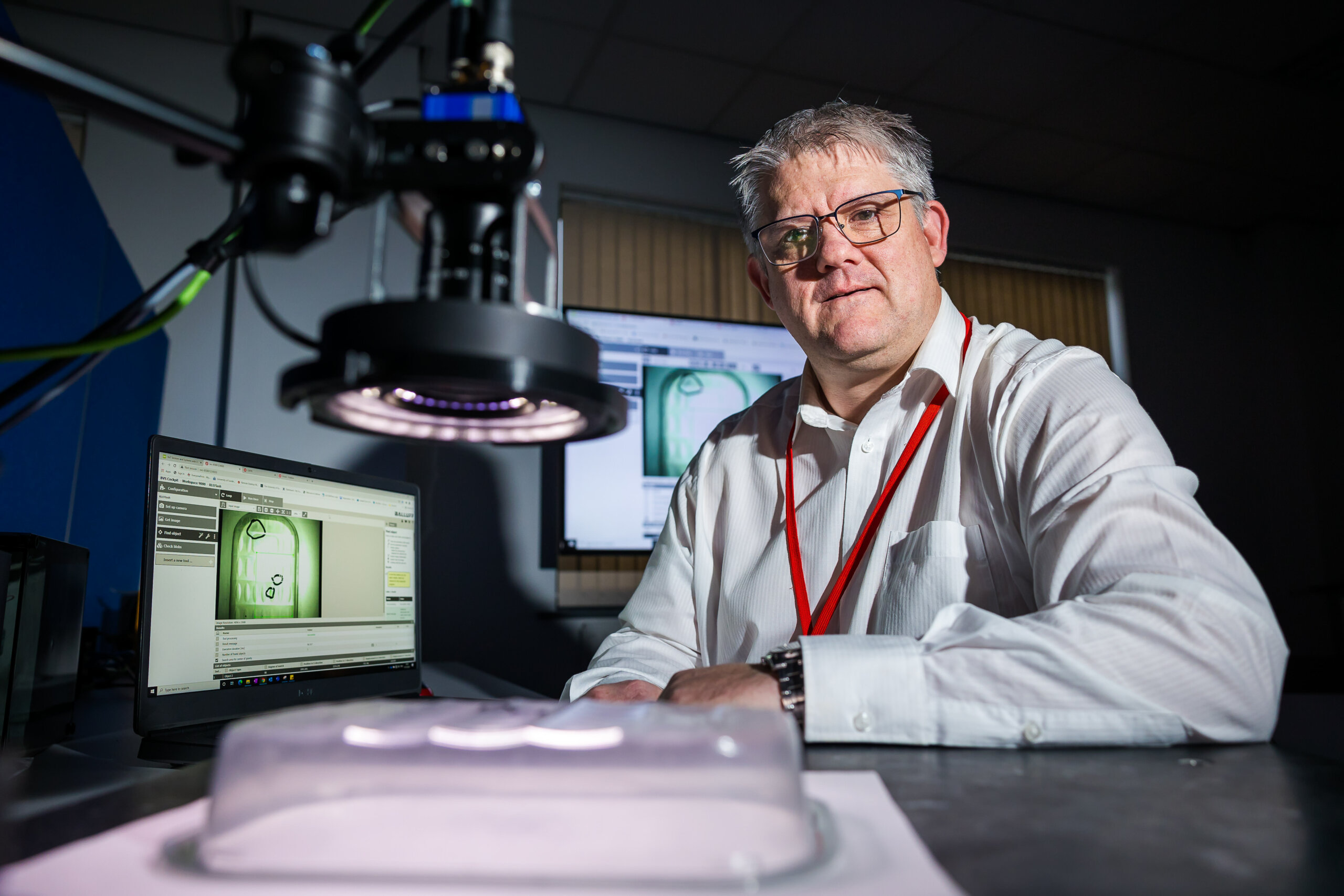

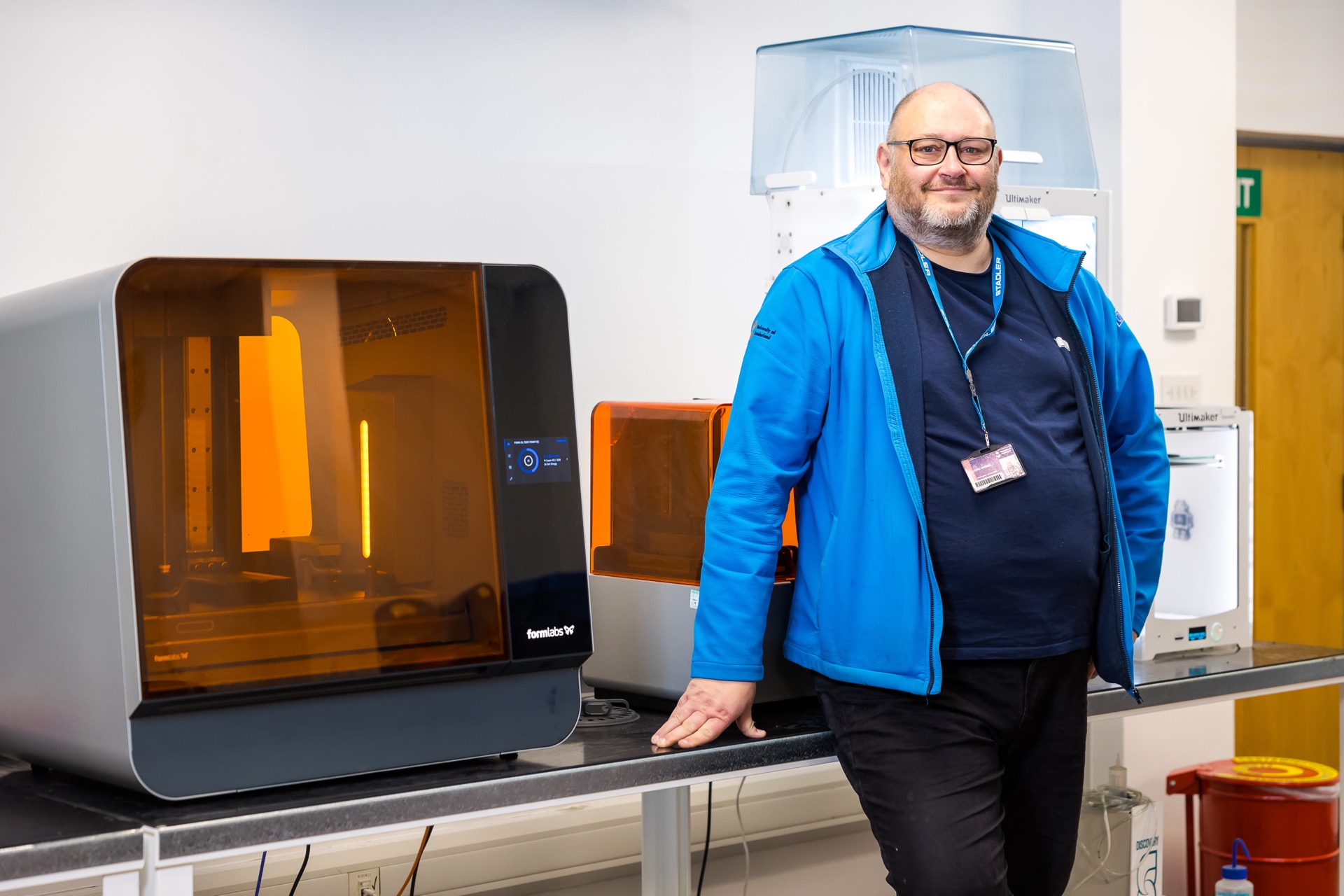

Most recently, this has seen the company attend a series of workshops held by experts from the University of Sunderland’s £10.9million Sustainable Advanced Manufacturing (SAM) Project to explore how it could improve processes and how current manufacturing techniques could blend with traditional and craft skills to improve its output.

Jeremy added: “We came across the SAM project almost by accident, but by taking part in the workshops alongside other niche manufacturers in the region, the extremely helpful expert staff on the programme were able to direct us towards a new way of visualising how technology could improve our processes, and lead us towards a new way of looking at our own work.”

Roger O’Brien, project and technical lead at the SAM Project, said: “We are delighted to have worked with Harrison and Harrison and to have helped them understand how current manufacturing techniques can be incorporated into such a long-established organisation.

“It’s a great example of how even the most traditional, niche of industries can benefit by embracing our support and how embracing modern day manufacturing techniques can help safeguard businesses for generations to come.”

For more information on Harrison and Harrison, visit: https://www.harrisonorgans.com/