SAM helps finetune Coronation organ manufacturer

The sound of the Westminster Abbey organ during the Coronation of Kings Charles III this weekend will bring music to the ears of staff at an historic North East manufacturer.

The programme is a collaboration between ERDF who is providing £5.77M funding (£2.6million from 2014-2020 and £3.1million from 2020-2023) and the University of Sunderland who are managing and, alongside industry, are investing £5.15M in delivery of this project.

The University of Sunderland have committed significant academic resources and recruited a team consisting of industrial and research specialists to support the delivery of both practical and research projects all fully funded to eligible SME’s

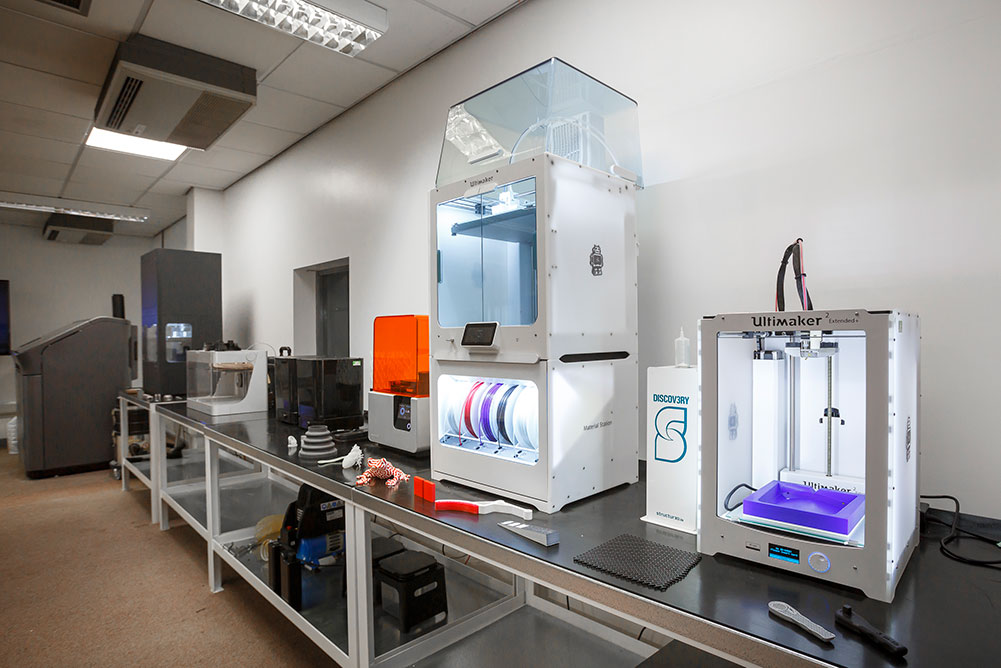

The project has over £1M of industry leading capital including 3D printers, I4 rigs and VR/AR equipment and software to encourage SME engagement with advanced technology.

The project also has grants of up to £50,000* available to support capital/product validation/tooling and other financial inhibitors to driving strategic development of both product and process.

Project & Technical Lead

Head of Research

Compliance Officer - Finance

Compliance Officer - Purchasing

Business Development Executive

Business Development Executive

Computer Aided Design and Engineering Specialist

Digital Engineering (VR & AR) Specialist

Product and Process Design Specialist

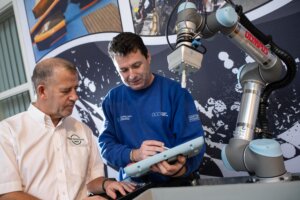

Automation and Robotics Specialist

Business Process Improvement and Simulation Specialist

Industry 4.0 and Electronics Specialist

Technical Team Support Administrative Assistant

Advanced Manufacturing Technician

The sound of the Westminster Abbey organ during the Coronation of Kings Charles III this weekend will bring music to the ears of staff at an historic North East manufacturer.

A family-owned manufacturer founded 165 years ago is envisaging a brighter future, after utilising cutting-edge technology to improve its products and processes.

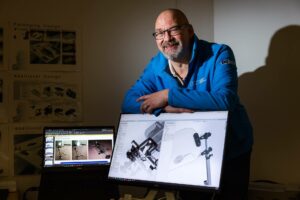

Interested in learning more about how 3D CAD could help your manufacturing business? Ian Barrett provides an insight…

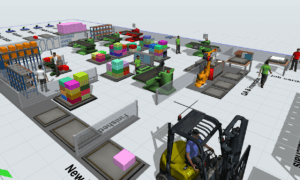

Rita Potts, Business Process Improvement and Simulation Specialist, provides an insight into the world of digital twinning within manufacturing.

North East engineering and manufacturing companies will be given support in driving operational excellence through Lean Tools & Techniques and Industry 4.0, with a series of events next month.

Industry 4.0 and electronics expert Richard Eynon explains how the latest technological advancements are impacting upon the manufacturing industry…

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.