Much has been made of the skills gap in the UK manufacturing industry in recent years and there are a number of factors contributing to this, including a lack of investment in new technology.

The manufacturing industry is heavily influenced by evolving technologies and new techniques are constantly helping to improve processes and the quality of end-products. There’s also no hiding from the increasing amount of computerisation involved in production processes, as well as the need for bespoke software solutions to meet growing demand, utilise different materials and manage workload.

As someone who has spent over 30 years’ in the industry, I’ve witnessed this first-hand. After working at one of the earliest adopters of industrial robots in the UK, Tallent Engineering (now Gestamp), I have seen the first robots they installed in the early 1980s grow to a robot population of over 1,200 at its Aycliffe site, with the pioneering technology helping bring continued success to the company and making it more competitive on the global stage.

Fast-forward 30 years and we have seen many more of the region’s manufacturers invest in emerging and mature technologies, such as AR/VR, which has been embraced by the likes of Caterpillar in Peterlee. However, technology advancement isn’t unique to large companies, despite the many pre-conceptions of such technologies being too expensive. In fact, this couldn’t be further from the truth.

Recently, we have worked with scores of North East SMEs to help them embrace new technologies, including companies such as Kail &Co, Heliguy, and AR Controls. Additive manufacturing in particular is increasingly competing with traditional manufacturing techniques even outside of prototyping and is a fundamental part of the 4th Industrial Revolution.

This is why, when reading the latest ‘Addressing skills and labour shortages post-Brexit’ report by the CIPD, I was surprised to see that only 9% of UK businesses plan to invest in technology as a way of addressing skill or labour shortages over the coming years. Technology is such a key driver within industry, which is why it’s now as important as ever to support businesses and employers to increase the adoption of new technology and support the skills development of staff.

Many SME manufactures are facing staff shortages and short-term interventions are needed in the way of quality business support and funding to overcome this crisis, making the investment in skills and technology more manageable and paving the way for long-term success. This support is exactly what the Sustainable Advanced Manufacturing (SAM) Project is here to provide, by helping SME manufacturers to innovate, grow and diversify.

Backed by ERDF, the Northern Powerhouse Initiative and the University of Sunderland, the SAM Project has a team of dedicated technical experts who work alongside the region’s SME manufacturers to support the implementation of product and process development, as well as the introduction of technology, at absolutely no cost to businesses. We also have matched-funding grants to help make the investment in new technology as affordable as possible.

Over the past few years, I have seen with my own eyes the many benefits that investing in technology can have on SMEs through some of the incredible projects we have been a part of, helping manufacturers embrace new technologies such as robotics, automation, design software, 3D printing and augmented and virtual reality. It’s technologies like these that open new doors for businesses and provide their employees with the capability to build upon their skills and ensure they are employable for years to come.

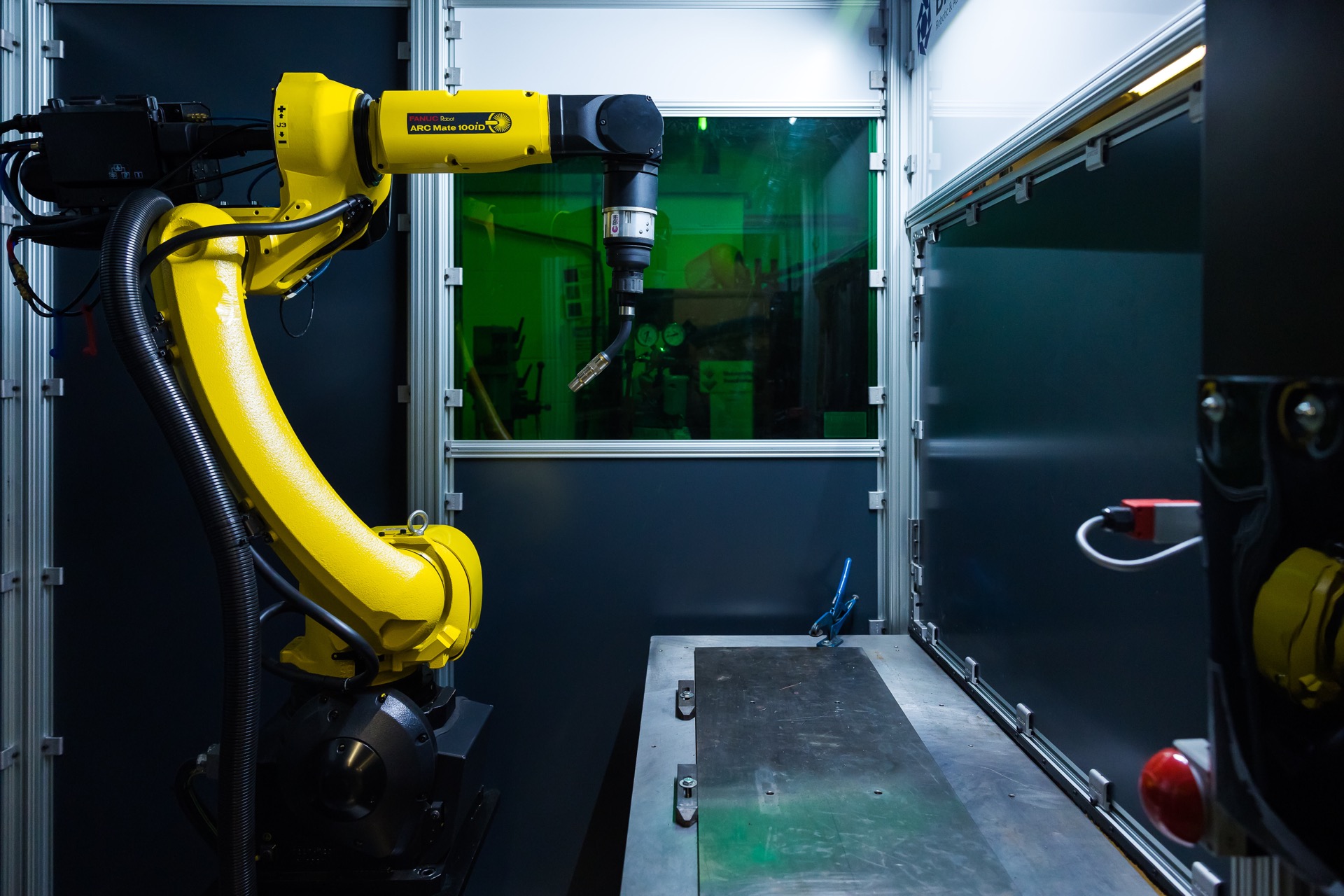

One such business that we were proud to support is specialist metal fabricators, Almet, who we helped explore the use of robotic welding technology through live demonstrations, showcasing to the team what they could achieve with this type of machinery based upon their specific needs. The Washington-based company has now increased its factory size by 12,000 sq ft and is investing in the technology itself to enhance processes. Not only did this safeguard jobs, but it will also create a number of highly skilled roles.

Another company we supported was precision engineering specialist, Ashgarth Engineering, providing funding to help with the purchase of a 3 axis vertical machining centre with a 4th axis attachment. This allowed the company to branch out into new markets and offer their current clients additional processes, leading to an increase in turnover and the creation of jobs.

However, tackling the skills and labour shortages post-Brexit and post-pandemic will take time and will also need to filter down to education, increasing awareness in schools about careers in manufacturing and increasing the number of manufacturing apprenticeships to help bridge the skills gap.

The manufacturing industry can provide employees with limitless potential to grow and learn as technology continues to advance. After all, just because someone lacks a certain skill, or the knowledge to operate new machinery, doesn’t mean they won’t pick it up quickly. If you have the willingness to learn and explore the opportunities in front of you, the skills shortage can be reduced, and your business can thrive.

For the SAM Project, we will continue to encourage the regions SME manufacturers to explore the support on offer and get in touch to find out how we can help. Our objective has always been the same, to build resilience among the region’s SME manufacturers, increase productivity and help not only safeguard, but also create jobs for the generations to follow.