A firm of County Durham engineers has stripped hours from its manufacturing times and is planning to venture into new markets, thanks to an elite team of experts.

Bignall Group is saving hundreds of manhours, investing in new machinery and already planning the second phase of its project working with a team of specialists from the Sustainable Advanced Manufacturing (SAM) Project.

SAM – which offers a range of support to SME manufacturing businesses in the North East LEP area – supported the Shildon-based operation following a full survey of Bignall Group’s production and workflow management systems, helping the company pinpoint bottlenecks in the process and then develop a plan for addressing the issues.

Bignall Group general manager, Mark Coatsworth, said the expertise of the SAM Project team had been vital in helping identify areas where improvements could be made.

“We were already examining our workflow system and identifying areas where we could eliminate bottlenecks and remove waste from the manufacturing process,” said Mark. “Bringing in the SAM team really helped speed that process up and we benefited from the fresh sets of eyes looking at how we operated.

“Like all businesses, we are always looking at ways to be more efficient, save on costs and generally just improve the way we do things. SAM really boosted that process, in one instance tackling a challenge in our sawing process that previously took a minute to remedy, but now takes about four seconds.

“We worked out the machines that were operating over-capacity and we addressed it, quickly speccing up two new pieces of kit that not only alleviated the capacity pressures, but expanded our ability to do more.

“Projects like SAM are essential to help firms, like ours, take that leap forward and begin operating on another level.”

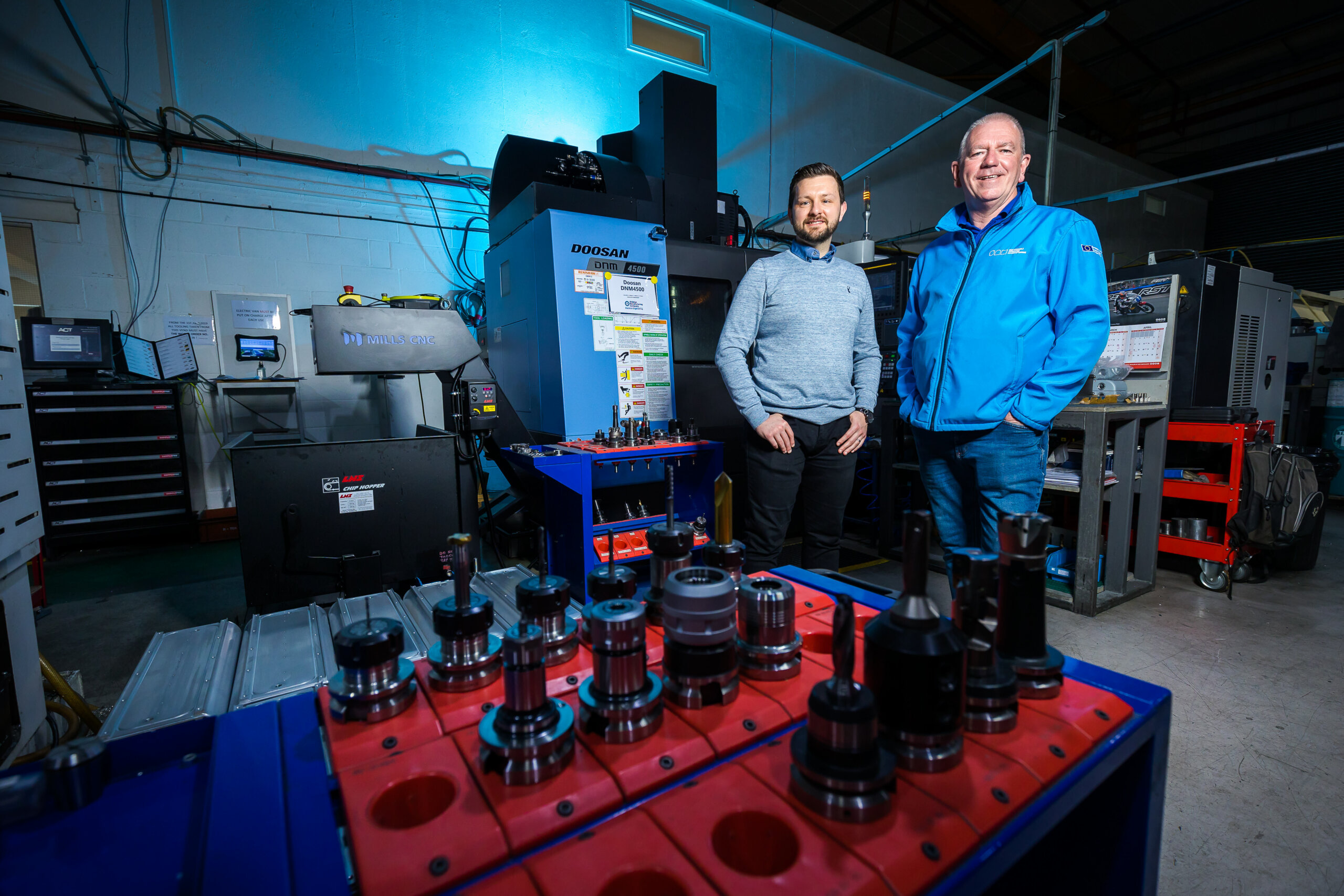

Bignall Group is made up of three complimentary businesses, Shildon Manufacturing Company provides CNC machining; Cobtec Cubicle Hardware supplies cubicle ironmongery into construction projects all across Europe; and Masterlube Systems designs, builds and distributes grease and oil lubrication systems worldwide from its facility in Shildon, County Durham.

SAM support not only helped pinpoint bottlenecks in the company’s systems, but also invest in a new 4-axis CNC machine and CNC lathe.

For over 40 years Bignall Group has been designing and developing light engineered products, with a manufacturing facility and multiple product groups. Selling in 20 countries across multiple industries, the company puts design and innovation at the core of everything it does. It currently employs 32 people, who work across all three businesses.

“Working with the SAM team last summer was an excellent experience and one that I’m very much looking forward to again, with the beginning of phase II of the project,” added Mark. “To be able to tap into that industry expertise has been invaluable for us.

“I’d absolutely recommend SAM to any SME looking to make efficiencies or improvements.”

Shildon Manufacturing Company remained open throughout the pandemic, with its clients providing items used in the NHS and the company even ventured into the world of PPE production at one point, designing, manufacturing and donating equipment to frontline workers.

Neil Taylor, automation and robotics specialist for the SAM Project, said: “Bignall Group is a fantastic cluster of businesses, each of which is really blazing a trail in its respective sector. It is a fantastic example of a company that has harnessed our region’s traditional industrial strengths and married them with leading-edge innovation.

“I look forward to continuing the great experience of working with the team at Bignall Group.”

The Sustainable Advanced Manufacturing (SAM) Project is a £10.9m collaboration between the European Regional Development Fund (ERDF), the University of Sunderland and the Northern Powerhouse Initiative and Industry, supporting the implementation of product and process development and the introduction of technology within the SME manufacturing base in the North-East Local Enterprise Partnership (NE LEP) area.

SAM offers four key support functions to businesses gearing up to grow, including access to technical expertise, with industrial specialists using their skill and expertise to guide businesses through the process of understanding and implementing technology; R&D, with a team of researchers able to support with the development of new products and processes; factories and facilities, including access to £1m of industry-leading advanced technology and equipment; and its grants scheme, that offers financial assistance to qualifying businesses.