Additive Manufacturing (AM) – or 3D printing as it is often referred to – is a method of creating a three-dimensional object, layer-by-layer, using a computer created design.

AM moves very quickly. Over the past few years, we have seen metal 3D printing go from something that is highly specialised and very high cost, to something that is achievable on desktop machines.

Material R&D has played a huge roll in the uptake of additive as materials are easier to work with and have far better properties. The software has also developed with some pace and we are now seeing topology optimisation and bespoke objects that could have only been produced via 3D printing.

My interest in 3D design began with design and modelling for 3D animation. The switch to making functional parts, especially those which are 3D printed, came about as I needed some parts for a research degree that I was working on at the time at the University of Sunderland.

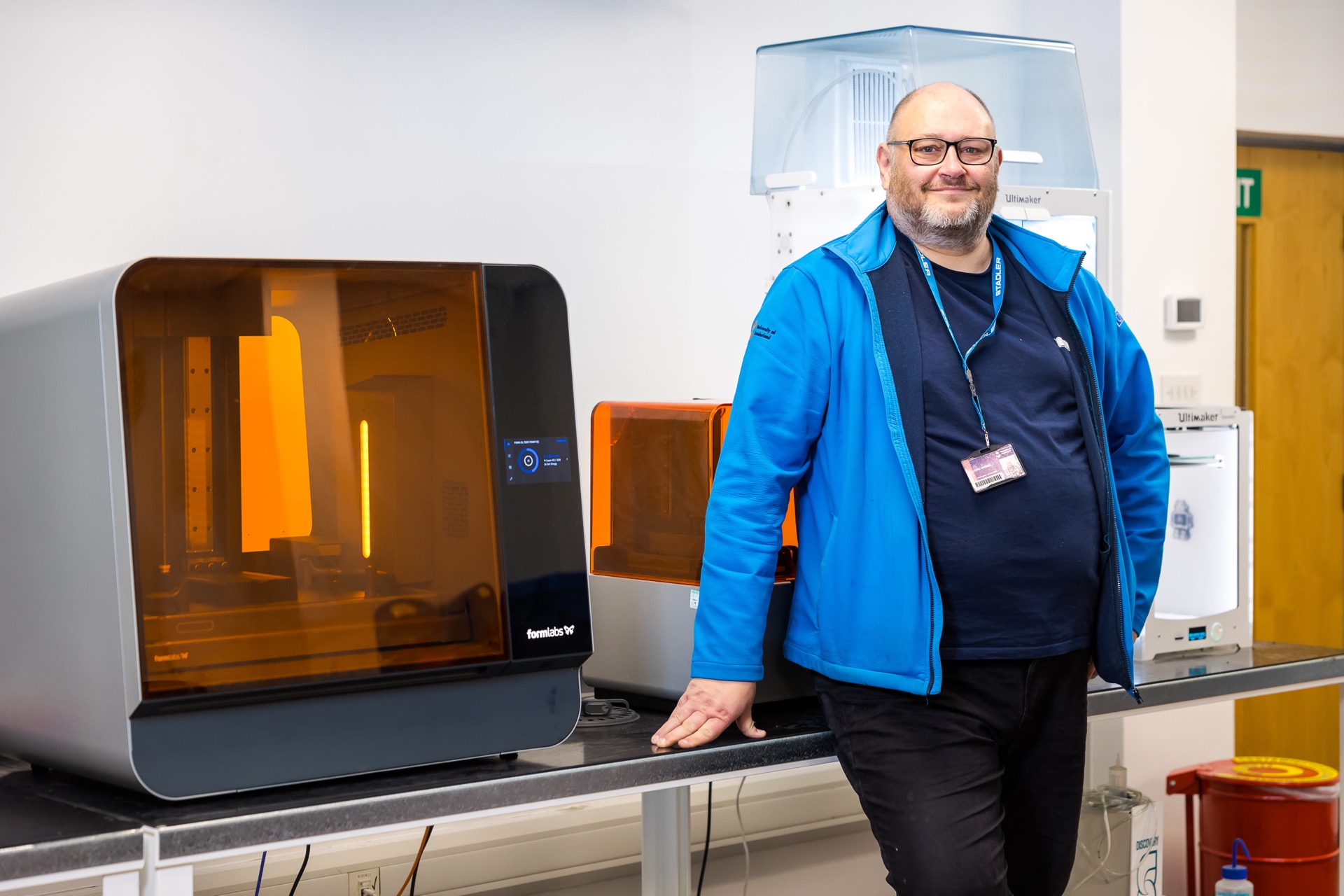

I joined the team at the university’s FabLab when that opened and supported a number of companies who were looking for 3D prototype parts and when the SAM Project began, it offered a fantastic opportunity to work with more advanced technologies.

Although I had worked with 3D printing prior to the SAM Project, it has been during my time here that I have really focussed on design for additive and how to get the most out of all the different technologies that are available.

I have worked on numerous AM projects at SAM, they include those that I have led on that focus on all aspects of additive, as well as supporting the work of my colleagues who frequently require parts and prototypes produced for their projects.

Additive is hugely impactful as it is one of the easiest ways to produce a part, simple or complex. This is allowing us to rapidly prototype and evolve designs.

In the North East, we are still seeing additive being used mainly for prototyping, but I think there is huge potential for it to have an impactful roll within traditional precision engineering firms for work-holding and jig production that could significantly increase productivity.

The two areas that we are seeing the most development in are materials and speed. Machines are now working with a broader range of materials than ever before, sometimes combining multiple materials in the same part. Machines are becoming faster and faster and in shorter runs can be more competitive than injection moulding. They also enable the mass customisation of parts in each build and allow complex assemblies to be printed as one piece.

For those interested in learning more about the uses and benefits of 3D printing, it has never been easier thanks to the support available through the SAM Project. To find out more about the support and how your business could benefit, contact the team today.