A SUNDERLAND-based engineering firm has expanded its presence in the city after investing in new premises and machinery during the pandemic

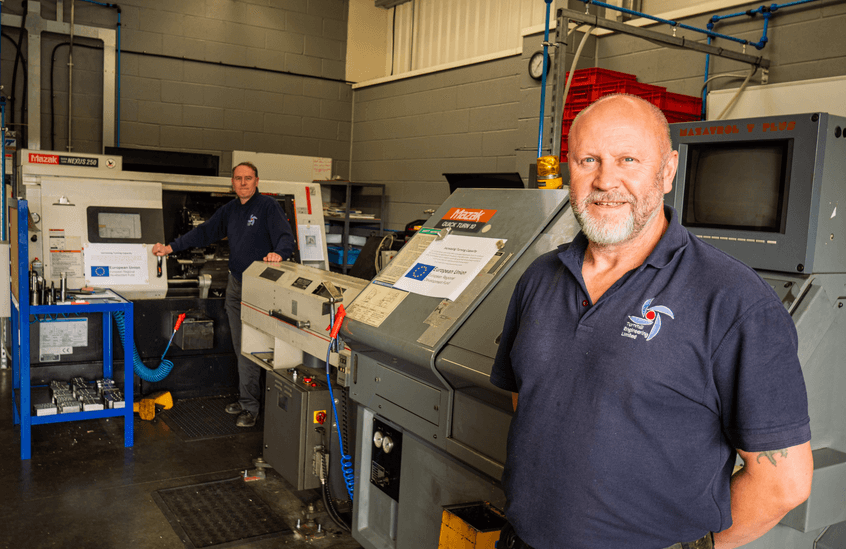

Turnmill Engineering, which is based at Washington Business Centre, works with businesses and individuals to help bring new products to market and improve production processes.

Specialising in the production of consumables, jigs and fixtures and machine components, the company was founded in 2018 by three industry experts boasting over 100 years’ experience between them and – boosted by an uplift in orders during the pandemic – is currently on track to record its best year to date.

The expansion, which has seen the firm increase its footprint three-fold, coincides with an investment in new machinery, including three Mazak CNC lathes machines, which will help the company achieve its target of increasing output by 50% over the coming months as it looks to ramp up production.

Andrew Howe, co-founder and operations director, said: “We try to concentrate on jigs, fixtures and production line improvements but if you were to take one look at our order book then you’d soon see just how much of a wide range of projects we work across.

“We started out in 2018 by completing a handful of projects for clients primarily in the automotive sector however since then – literally by word of mouth – we have diversified and established ourselves in several key sectors including pharmaceuticals, motorsport and construction.”

Turnmill Engineering has grown by 30% year-on-year since its launch however its busiest period to date proved to be while the UK was placed in lockdown during the Covid-19 pandemic.

“We welcomed on board a number of new customers during the pandemic and this was mainly due to our production breakdown and line improvement service,” Andrew added.

“With manufacturers the world over forced to adhere to strict social distancing measures, companies began exploring new ways to reduce production costs and we have been fortunate in the fact that we’ve been able to help through the provision of new fixtures, jigs and product development and hopefully we can continue building on that momentum post-covid.”

Turnmill moved to Washington Business Centre after being introduced to the office space by Sunderland City Council’s business investment team and being impressed by its flexibility and its ability to accommodate its future growth plans, which will see the company continue adding to its headcount over the next 12 months.

Andrew said: “What really impressed us about Washington Business Centre was the flexibility it offered us to grow. Since moving to the centre two and a half years ago, we’ve already expanded three times into larger units which has allowed us to continue scaling while causing minimum disruption to the business.

“Another advantage was its location, as it is situated ideally on the Nissan commuter belt. The North East is home to one of the largest automotive clusters in Europe and to be right at the beating heart of this has proven ideal for us as a company and has played a key role in helping us grow.

“We now have five members of staff and – following this latest move and the investment in new machinery – are looking to create a further two roles over the next 12 months, one of which will be an experienced engineer and one which will hopefully be at entry-level as we look to pass on our knowledge and know-how to the next generation, too.”

Turnmill’s investment in new machinery was also supported by the University of Sunderland’s Sustainable Advanced Manufacturing (SAM) Project, which provides matched-funding and business support to SME manufacturers across the North East LEP area and recently secured a £6 million extension taking the programme to 2023.

Ken Teears, project manager at SAM, said: “We were delighted to work with Andrew and the team at Turnmill to help identify new opportunities for growth and invest in the machinery required to take the business to the next level.

“The SAM Project was set up to support the implementation of product and process development in order to help the region’s SME manufacturers unlock their growth potential and Turnmill is yet another great example of this in action.”

Councillor Graeme Miller, leader of Sunderland City Council, said: “Washington Business Centre was launched to help SMEs scale and grow and to see Turnmill Engineering continuing to innovate and expand its presence at the business hub is a fantastic success story not only for the centre but for the city as a whole and I think I speak for everyone at the Council when I say we’d like to wish them all the best for the future.”